Page 4 - Cable Art Inc Catalog

P. 4

Cable Art Incorporated

Architectural Products

Advantages of Swageless Fittings

Swaging is the term used for attaching fittings to the cable. With swageless fittings, the cables can be installed at

Swageless fittings are installed on the cables by hand at the same time the railing frames are installed. There is no

the job site. With swageless fittings, at least one cable waiting for exact measurements that would be required if the

end does not contain a fitting when delivered to the job cables were supplied with fittings on both ends of the cable.

site. Fittings are larger than the diameter of the cable, so, Swageless fittings are generally more costly than fittings that

since only bare cable is fed through intermediate elements are swaged. However, on smaller projects, using swageless

between terminating end posts, holes in the intermediate fittings often results in savings when the cost of renting or

elements can be drilled close to the diameter of the cable. purchasing the equipment necessary to swage the fittings

Hence, there is a tighter fit between cable and frame than on site is considered.

there would be if the cables were supplied with fittings on

both ends. Swageless fittings are offered for use with 1/8”, 3/16” and

1/4” cable, so they are not a choice for projects using larger

diameter cables.

Advantages of Swaged Fittings

If fittings are swaged on site when the cables are installed, exact measurements must be supplied for the factory to

the intermediate elements between terminating end posts swage the fittings onto the cable and, with fittings already

can be drilled close to the diameter of the cable, because attached to the cables, intermediate element holes

there are no fittings to pass through the holes in the posts. need to be drilled oversize for the fittings to pass through

There is a tighter fit of cable to frame than there would be for installation.

with the larger holes required if fittings are swaged on both Swaging requires special equipment that can be purchased

ends before the cables are strung through the posts. or rented from the factory. Swaged fittings are generally

An alternative to swaging on site (or using swageless less expensive than swageless fittings, so on larger

fittings) is to have the fittings swaged on both ends of the projects the savings in using swaged fittings may more

cable by the factory. The disadvantages, however, are that than offset the cost of the equipment.

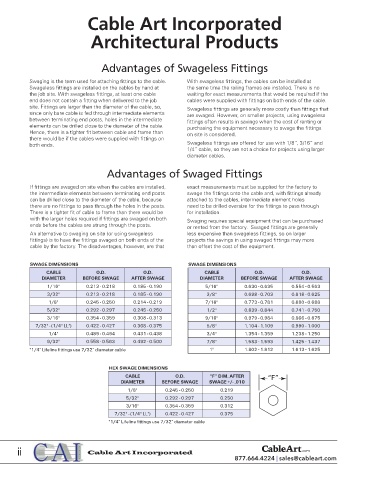

SWAGE DIMENSIONS SWAGE DIMENSIONS

CABLE O.D. O.D. CABLE O.D. O.D.

DIAMETER BEFORE SWAGE AFTER SWAGE DIAMETER BEFORE SWAGE AFTER SWAGE

1/16" 0.213 - 0.218 0.185 - 0.190 5/16" 0.630 - 0.635 0.554 - 0.563

3/32" 0.213 - 0.218 0.185 - 0.190 3/8" 0.698 - 0.703 0.618 - 0.625

1/8" 0.245 - 0.250 0.214 - 0.219 7/16" 0.773 - 0.781 0.680 - 0.688

5/32" 0.292 - 0.297 0.245 - 0.250 1/2" 0.839 - 0.844 0.741 - 0.750

3/16" 0.354 - 0.359 0.308 - 0.313 9/16" 0.979 - 0.984 0.866 - 0.875

7/32" - (1/4" LL*) 0.422 - 0.427 0.368 - 0.375 5/8" 1.104 - 1.109 0.990 - 1.000

1/4" 0.489 - 0.494 0.431 - 0.438 3/4" 1.354 - 1.359 1.238 - 1.250

9/32" 0.558 - 0.563 0.492 - 0.500 7/8" 1.583 - 1.593 1.425 - 1.437

*1/4” Lifeline fittings use 7/32” diameter cable 1" 1.802 - 1.812 1.613 - 1.625

HEX SWAGE DIMENSIONS

CABLE O.D. “F” DIM. AFTER “F”

DIAMETER BEFORE SWAGE SWAGE +/- .010

1/8" 0.245 - 0.250 0.219

5/32" 0.292 - 0.297 0.250

3/16" 0.354 - 0.359 0.312

7/32" - (1/4" LL*) 0.422 - 0.427 0.375

*1/4” Lifeline fittings use 7/32” diameter cable

ii

Cat21 S1 i-x.indd 2 12/3/20 12:09 AM