| Cable Diameter | Typical Applications |

|---|---|

1/8" | *See note below. Can be used on horizontal railings where there is little or no pedestrian traffic or where railing does not need to meet code requirement (such as where there is little or no drop off). Can be used on vertical railings, which are not as susceptible to heavy shock loads as horizontal railings. |

3/16" | Most commonly used diameter for pedestrian railings. |

1/4" 5/16" 3/8" | Diameters larger than 3/16" can be used where a larger diameter is desirable from a visual / aesthetics standpoint. In areas subject to extreme abuse (such as school or heavily trafficked public area) 1/4" diameter or larger is recommended. |

*1/8" diameter cable can be vulnerable to failure under shock loads caused by abuse. 3/16" and larger cable diameters have significantly higher load ratings than 1/8" and are, therefore, not as susceptible to failure as 1/8".

Cable Minimum Breaking Strengths

| Cable Diameter |

Minimum Breaking Strengths (Lbs.) For Following Cable Constructions in Type 316 Stainless Steel | ||

|---|---|---|---|

|

1x19

|

7x7

|

7x19

|

|

|

1/8"

|

1,780

|

1,360

|

1,300

|

|

3/16"

|

4,000

|

3,300

|

2,900

|

|

1/4"

|

6,900

|

5,500

|

4,900

|

|

5/16"

|

10,600

|

7,600

|

7,600

|

|

3/8"

|

14,800

|

11,700

|

11,000

|

Cable Railing Design Parameters and Constraints

This section will address the issues encountered while designing a horizontally run cable railing system.

A horizontally run series of cables used as in-fill in a railing is legal in most jurisdictions. A few places, however, do not allow the "ladder effect" of horizontal in-fill elements. Therefore, the first step to be taken is to determine if the jurisdiction of the site will allow a "ladder effect" type of railing. If horizontal railing is not allowed, we offer a vertical cable railing system, which is described later on in this section.

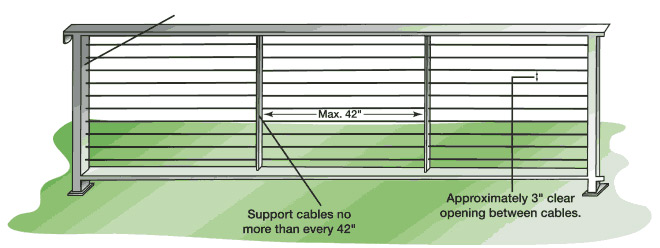

Spacing the intermediate members, which are posts and/or braces: These posts / braces will support the cable as it passes through the walls of the railing frame. (An intermediate post runs from the top rail to the mounting surface. A brace is a lighter weight material placed between posts, its primary purpose being to support the cable.) Cable can be run quite long distances between terminating ends (150 ft. or more, depending upon railing configuration), but will need to be supported at intervals between end posts, to avoid cable deflection in excess of that permitted by building codes. When a rigid cable construction is used, such as 1x19, the spacing between posts and/or braces should not exceed 42".

|

Spacing of the cables vertically is critical to minimize deflection of the cables under a vertical load. The recommended vertical spacing is approximately 3" free opening between cables when they are installed.

|

Tension of the cables and the construction of posts to which mounting and tensioning hardware is attached: deflection of the end posts must be minimized, and this is where we have found the most mistakes made in the design of the railing framework. An incredible amount of tension is generated on an end post when you have ten or more lines, each tensioned at 200 lbs. or more over a height of 36" to 42". Often, designers and fabricators inexperienced in cable railings will not recognize the amount of the tension applied to the posts. The end result all too often is end posts which will bend considerably as the cables are being tensioned, or with a railing where the cables cannot be properly tensioned without an unacceptable amount of post deflection. The posts to which hardware is mounted must be constructed so that they will not deflect perceptively as the cables are tensioned to loads of 200 lbs. or more. |

All of these variables work together to minimize the deflection of the cable so as to not allow a 4" sphere to pass between the cables when they are properly tensioned in a well-designed frame.

|

Issues encountered in designing a railing using vertically run cables as in-fill. Top and bottom rails are necessary in a vertical railing using cable, because mounting and tensioning hardware is attached to top and bottom rails instead of end posts. Schedule 80 pipe or 2"x2"x1/4" square tubing for both the top and bottom rail is recommended, because of the forces applied when the cables are properly tensioned. However, the amount of force that can be applied to a vertical cable is generally less than can be applied to a horizontally run cable. The result is less force being applied to the mounting and tensioning fittings. Therefore, you may consider using 1/8" diameter cable with a vertical system, where you may not want to use it in a horizontal system. |

Horizontal Run Cable Railings - Double End Post Construction

2"x 1"x .120" or 3"x 1"x .120" structural steel posts with stainless steel spacers

2"x 1" or 3"x 1" top and bottom rail and intermediate posts (if applicable)

|

Frame components can be carbon steel or stainless steel. This style has been designed to perform satisfactorily when subjected to the tension encountered when multiple load points (cables) are attached and tensioned properly to your end posts (200 lbs. or more per line). Detailed downloadable drawings (see later in this document) show proper spacing of the cables vertically on the end posts that allow for cable flex within allowable limits to meet code requirements that a 4" ball shall not pass through at any point. This railing style uses an end post with two vertical members separated by stainless steel spacers. Intermediate posts are only 1" thick. This construction is strong yet its elements are relatively thin, so there is little visual obstruction created by the frame. Note the tubed corner sections that are illustrated. They replace corner posts with hardware mounted on two sides or two posts with cable pulled between them. The cable runs through tubes welded to two posts. It makes a nice looking corner with uniform curves going around the corner. See Tubed Corner Sections detailed drawings. |

2"x 2"x .250" wall structural steel end post construction

2"x1" top rail and bottom rail (if applicable)

|

Frame components can be carbon steel or stainless steel. This style has been designed to perform satisfactorily. When subjected to the tension encountered when multiple load points (cables) are attached and tensioned properly to your end posts (200 lbs. or more per line). Detailed downloadable drawings (see later in this document) show proper spacing of the cables vertically on the end posts that allow for cable flex within allowable limits to meet code requirements that a 4" ball shall not pass through at any point. Even though the end posts are 2"x2"x.250", intermediate posts can be 2"x1"x.120" to minimize the bulkiness of the frame. |

Round pipe and round steel tubing posts

|

Frame components can be carbon steel or stainless steel. This style has been designed to perform satisfactorily when subjected to the tension encountered when multiple load points (cables) are attached and tensioned properly to your end posts (200 lbs. or more per line). Detailed downloadable drawings for 1-1/4", 1-1/2" and 2" standard pipe are available. Minimum schedule 80 pipe is required for your end posts. The drawings show proper spacing of the cables vertically on the end posts for standard round pipe. Those spacing allow for cable flex within allowable limits to meet code requirements that a 4" ball shall not pass through at any point. Round tubing can be used with a wall thickness at least comparable to schedule 80 pipe. If you are using round tubing, the downloadable drawings must be modified to allow for the different diameters of tubing versus pipe. Note the tubed corner sections that are illustrated. They replace corner posts with hardware mounted on two sides or two posts with cable pulled between them. The cable runs through tubes welded to two posts. It makes a nice looking corner with uniform curves going around the corner. See Tubed Corner Sections for detailed drawings. |

Other metal frame materials for cable railing

|

Frame components other than those shown in this guide can be used using carbon steel or stainless steel. Other frame styles should be engineered to perform satisfactorily when subjected to the tension encountered when multiple load points (cables) are attached and tensioned properly to your end posts (200 lbs. or more per line). Center-to-center spacing of the cables vertically is critical to allow for cable flex within allowable limits to meet code requirements that a 4" sphere shall not pass through at any point. |

|

Frame components can be carbon steel or stainless steel. These styles have been designed to perform satisfactorily when subjected to the tension encountered when multiple load points (cables) are attached and tensioned properly to your end posts (200 lbs. or more per line). Detailed downloadable drawings show proper spacing of the cables vertically on the end posts that allow for cable flex within allowable limits to meet code requirements that a 4" sphere shall not pass through at any point.

|

Tubed corner sections

|

Tubed corner sections can replace corner posts with hardware mounted on two sides or two posts with cable pulled between them. The cable runs through tubes welded to two posts. It makes a nice looking corner with uniform curves going around the corner. Detailed downloadable drawings are available and can be used or modify for your project. Frame components can be carbon steel or stainless steel, and your vertical posts can be the same material used for your intermediate posts. |

Material specifications for cable railings with horizontally run cables

NOTE: We strongly recommend stainless steel for exterior applications.

* Note: Minimum Wall thickness shown is for double end post construction using two rectangular posts separated by stainless steel spacers. We do not recommend .120" wall for a stand-alone end post. |

||||||||||||||||||||||||||||

* Note: For tubing, use wall thickness approximating wall thickness of pipe schedule shown. |

||||||||||||||||||||||||||||

| See the list of CAD drawings that can be downloaded for engineered tubular steel and pipe railings together with material specifications for each railing. The material specifications above are intended as general guidelines for use in designing a railing for which drawings are not available on the web site. The design professional is responsible for engineering the railing to meet building code requirements. | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Stainless Steel Spacers for Double End Post Railing Construction

Stainless Steel Spacers For Use With Invisiware Fixed Tabs

|

||||||||||||||||||||||||||||

| Corner Section Tubing For use in 90° corners using tubing in the corner sections through which the cable passes. *See Note.

|

||||||||||||||||||||||||||||

Downloadable DXF Drawings - Horizontal Cable Railing

Vertical cable railing frame styles

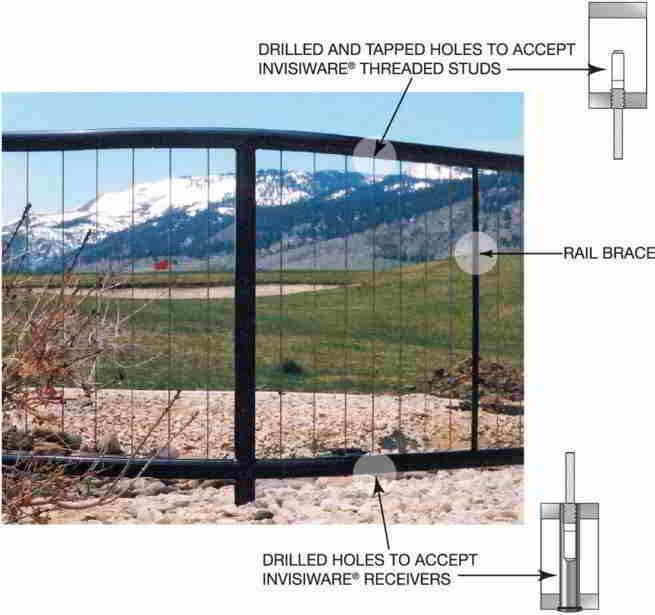

This cable railing frame style facilitates the use of cables in the vertical position, running from the top rail to the bottom rail.

Drawings later in this document illustrate fabricating the railing from pipe. Square or rectangular tubing can also be used, but we recommend a minimum wall thickness of 1/4" in your frame material.

An Invisiware® Threaded Stud on one end of the cable is screwed into a drilled and tapped hole in the underside of the top rail. An Invisiware® receiver is inserted into a hole drilled through the bottom rail. A threaded stud on the other end of the cable is inserted into the receiver, and the cable is tensioned by turning the receiver with an Allen wrench.

Because the Invisiware® receiver goes all the way through a hole in the lower rail, a stainless steel frame must be used in exterior applications, to prevent rust in the frame.

This style has been designed to perform satisfactorily when subjected to the tension encountered when multiple load points (cables) are attached and tensioned properly on the top and bottom rails (200 lbs. or more per line). Detailed downloadable drawings show proper spacing of the cables horizontally on the top and bottom posts to allow for cable flex within allowable limits to meet most code requirements (that a 4" sphere shall not pass through at any point). Note that we recommend special rail braces to replace every eighth cable, to keep the top and bottom rails from bending when the cables are tensioned.

|

Material specifications for railings with vertically run cables

NOTE: For exterior applications, specify stainless steel to prevent rust in the railing frame.

Carbon or Stainless Steel Structural Tubing

Round Steel or Stainless Steel Pipe **See note

|

|||||||||||||||||

| Rail Braces For use in place of a cable at least every eighth cable on 3.25" centers between structural posts to support top and bottom rails under tension.

|

|||||||||||||||||

Downloadable DXF drawings - Vertical cable railing styles